Coax Soldering

Case Soldering

Power Connector Soldering

Coax Soldering

Induction Soldering

What Is Soldering

Induction Soldering Advantages

Soldering is a method of joining metal parts using a filler metal called solder. The solder melts at a temperature below the melting point of the metal parts, typically less than 600F, and flows onto the surface of the metals. A solder bond is chemical in nature rather than a physical bond as achieved when using brazing and welding processes.Typically, soldering flux is required to clean the surfaces of the metals for proper bonding. Most solders used are a tin/lead alloy melting around 370F. Lead free solders consisting primarily of tin with a small amount of silver and copper are also frequently used to eliminate the use of lead for safety and environmental reasons. Lead free solders melt at a higher temperature and are more difficult to use than tin/lead.

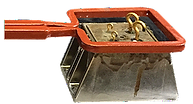

The lid on this electrical enclosure is evenly heated to uniformly flow the solder into the joint. The entire solder joint can also be heated at one time for removal of the lid if required.

Why Magneforce Induction Soldering

Magneforce Induction Soldering systems are used to provide non-contact, repeatable heating for a variety of soldering applications. The magnetic field can be focused and controlled to evenly heat the metal parts, eliminating cold joints and burnt flux. Setup properly heating is identical part to part. There is no electrode or soldering tip to wear out. Some of the many applications include soldering coax cable connectors, sealed enclosures and cans, automotive windshield connectors, power cables, electrical connectors and soldered assemblies.

Insulating materials and other nearby plastic parts are not affected by the heating. Larger parts, such as filters, condenser cans and electronics enclosures can be evenly heated with even solder flow around the entire component while enabling easier desoldering as the entire joint area can be heated at one time.

Soldering Fitting To Coax Cable

Using A "C' shape coil for access

Lower Labor Costs, Reduce Skill Required

Proper soldering requires a trained and experienced operator. With induction soldering, the operator just needs to load the parts into the fixture and hit the ON button.

Repeatable Heating

The heat delivered to the part is the same every time for consistent quality solder joints

No Burned Fingers

The induction soldering head is stays cool during and after heating, increasing safety andgreatly reducing the chance of burned fingers in this terminal soldering operation

Heating Head Stays Cool In

This Terminal Soldering Setup

Improve Part Quality - No Cold Joints

The surfaces to be soldered must be brought to temperature simultaneously. If they are not the solder can flow on one surface only producing a difficult to detect cold joint. A properly setup induction soldering process eliminates cold joints.

Electrical connections internal to this housing are reliably soldered without affecting the plastic housing.

Turnkey Systems & Fixtures

Custom Heating Coil Manufacturing

Proper heating coil design is essential to any inductionsoldering process. Small changes in the coil can make the difference between good joints & cold joints.

We manufacture all heating coils in house, enabling rapid prototypes and the ability to refine the coil design and focus heating as required.

Flat, encapsulated heating coil mounts to fixture for soldering connectors to automotive windshields

No Charge Sample Processing

We will process your sample parts and return them to you for evaluation. All process parameters including heating power, heating time and temperature. Setup pictures and/or videos will also be included.

Made In The USA

All Magneforce induction heating systems for soldering are manufactured at our facility in Warren, Ohio.

We can supply cost effective process fixtures and part nests to complete your soldering process or complete systems ready to run . Accurate, consistent part setup is the key to quality, repeatable solder joints.

Fixture Allows Easy, Exact Part

Load & Unload. Applies pressure

to part to seat lid.