Heating 2 Carbide Inserts For Brazing To A Tool Shank

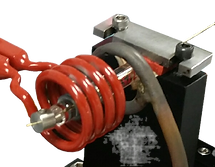

Heating Coil Formed to heat 2 surfaces of motor housing lid for heat shrink operation

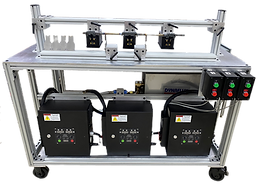

HS5000R2TS Induction Heater with touchscreen controls

Heating 2 Carbide Inserts For Brazing To A Tool Shank

Induction Heating

Systems

Why Magneforce Induction Heating

Many applications using induction heating must be set up correctly to provide satisfactory heating results. If the system is not set up properly, heating will be inefficient and ineffective. This may result in poor, inconsistent part quality or the need for a larger more expensive induction power supply.

Using our Built In The USA Heat Station induction heaters, over 150 years of combined experience and 1000's of systems sold, Magneforce will design, fabricate, test, videotape and guarantee your heating process. Complete in house heating coil development capability enables us to fine tune and focus the heating . With in house CNC and additive manufacturing capabilities we can provide process fixtures to give you ready to use systems.

Rectangular Carbide Is Silver Brazed To A Steel Carrier

The ID of a shaft is heated for shrink fit insertion of an impeller

The heating coil is customized to evenly heat the tube and fitting for best braze

Rectangular Carbide Is Silver Brazed To A Steel Carrier

Induction Heating Applications

-

Carbide Brazing

-

Copper & Steel Brazing

-

Component Soldering

-

Thermal Shrink Fitting

-

Epoxy Curing

-

Plastic Extrusion

- Threaded Insert Heating

-

Annealing

-

Melting

-

Diamond Brazing

-

Coax Cable Soldering

-

Catheter Tipping

-

Windshield Soldering

- Process Heating

How Does Induction Heating Work

An induction power supply converts standard 50/60hz AC power to a high frequency output and delivers this energy to the heating coil.

The heating coil consists of a copper winding custom formed to fit the part and can be made in a wide variety of shapes and sizes. The coil creates and focuses a magnetic field on the part where it's needed to produce the heating required.

A brass shell is dropped into the heating coil, heated to a pre-set temperature and then released into a quench.

Why Use Induction Heating

What Makes An Induction Heating System

What is Induction Heating

Induction heating is a flameless, non-contact, rapid and highly controllable method of heating metal parts using a high frequency electromagnetic field.

When a metal part is inserted into the alternating magnetic field, localized electrical currents will be induced in the part. The resistance of the metal to the flow of these currents causes it to heat up.

-

Improve Part Quality

-

No Open Flame

-

Save On Energy Cost

-

Read Temperature

-

Reduce Operator Skill

-

Fast, Clean Heating

-

Precise Heat Control

-

Consistent Heating

-

Reduce Part Cleanup

-

Focus The Heat

A basic Magneforce induction heating system consists of an induction heater with matching transformer, a heating coil, and a part or assembly to heat.

The heating coil is usually water cooled and custom designed for the application. It can be fabricated in a wide variety of shapes and sizes as required to heat the part.

Water cooling, usually in the form of a recirculating coolant system. is required for most systems. Typically, Dynaflux coolant systems are used. Clean, in house water can be used if available.

Operating controls, such as cycle timers, output power control, remote actuators, power control footpedal, thermocouple or infrared temperature controllers may be required, depending on the application. The system shown above is PLC controlled and all operating parameters are entered using the remote touchscreen control..

Many applications benefit from using process fixtures to hold the part(s) firmly and in the same location to insure even heating for repetitive parts. The fixture must be properly designed to prevent heating and heatsinking of fixture components, reducing heating efficiency and affecting the heating process. Magneforce can supply the fixture or work with the customer for their in house fixture design.

• Induction Heater

• Heating Coil

• Load (Part To Heat)

• Coolant System

• Controls

• Fixture

HS5000R2TS Induction Heater

HS5000R2 Heating System With Fixture

3 Position Fixture For Carbide Brazing

Tool chuck is being heated to shrink fit a cutting tool into place

A steel shaft is heated in three locations simultaneously. Carbide inserts will be brazed into each location. The middle position heats a little slower to allow the end carbides to be set in position first.

The shaft to be annealed and the induction heating coil are located inside the enclosure. The coil moves along the shaft to selectively anneal preset locations.

Dynaflux 2200V

Coolant System

HS5000R2

Induction

Heater

Touchscreen

Control

Heating Coil &

Part Inside

Induction Heating Products

Magneforce offers a range of products to implement and support your induction heating application. Products include our Heat Station 2500R2 & 5000R2 induction heaters with remote output transformers, custom designed & fabricated induction heating coils, Magne AC3 air cooled induction

heaters with plug in lightweight heating heads and Dynaflux coolant recirculators. We also offer a variety of controls and accessories and the capability to design/build custom systems and fixtures for processing your parts.

Induction Heating Applications

Induction heating can be used whenever precise, consistent and rapid heating of metal parts is required. Heat Station heaters are currently used in Industrial, Medical and Scientific processes. These include the brazing of tools, tubes and assemblies, soldering connectors and terminals, heating inserts for hot pressing into plastic parts, induction heat shrink fitting

cutting tools, gears, rings and bearings, preheating for welding and molding operations, melting, heat staking, extruder barrel heating, curing epoxies, coatings and adhesives, heating catheter tipping molds, annealing, stress relieving and a variety of specialty applications. We have setup and applied thousands of heating systems. CALL TODAY.

4 carbide teeth are silver brazed to this heavy duty debarking tool

Shielded coax cable is soldered to a stainless steel sensor head

A section of hardened shafting is

annealed prior to machining

A bearing housing is expanded to induction shrink fit components

Brass and steel threaded inserts are rapidly heating for pressing

into plastic molded parts

A motor housing shell is heated & held at temp to cure epoxy securing the ferrites inside

A glass tipping mold is heated to form the end tip on a catheter

A steel plate is evenly heated prior to being rubber coated

No Charge Induction Heating Evaluation

If you have a project to heat a part or assembly and think induction might be the way to go, contact us and we can help. Our equipment may not be what you need. If it is not suitable we will let you know and tell you why not. It might be the application isn't good for induction or our equipment is not suitable due to frequency or power capability. If it is OK we would be happy to review your application

and discuss it with you. We offer no charge sample testing. We will test heat your part with a custom designed heating coil at no charge and provide you with finished samples, a process report including the model induction heater used, the heating coil, the setup and power and time settings. We can also provide a video of the sample run and thermal imaging when applicable.

About Us

-

Designing and building custom induction heating systems since 1986.

-

All equipment manufactured in Warren, Ohio, USA.

-

Experienced Sales, Service and Engineering Team.

-

In house service and repair.

-

No charge process evaluation and sample parts testing.

Magneforce Inc. has supplied thousands of induction heating systems since 1986, for applications ranging from the routine to the innovative. In many cases we have developed successful heating solutions where the customer has not been able to identify any alternatives.

With over 150 years of combined experience in custom applications and heating coil development we can provide unique solutions to your heating problems.

Heat Station heating systems are currently used in industrial, medical and scientific applications. We service what we sell. All equipment, including induction power supplies, heating coils and fixtures, are manufactured in the USA at our facility in Warren, Ohio.

We specialize in heating coil manufacture. In addition to providing induction heating coils for Magneforce equipment, we can supply replacement coils for all competitive equipment, usually at significantly lower prices.